project matrix Ben Shen z5243949

PROJECT MATRIX

BENV7813

Contemporary Fabrication Techniques

Ben Shen

Z5243949

1.

Metropol

Parasol

Key Concept

The first architectural precedent I chose is Metropol Parasol

which is designed by Mayer H.

Architects and engineered by Arup in Saville, Spain. There are three reasons choosing this specific precedent for

fabrication. Firstly, this project extended the possibility by pushing

the plywood, steel and glue further to create the one of biggest timber

structure in the world (ARCHITECT). Therefore, the exploration of plywood

proportion is expected to achieve in this fabrication process. Secondly, this

project highly depends on the digital design. This mean I also could be

familiar with these digital processes to create such an intersection structure.

Finally, the main structure of this

project is made of plywood which is shaped by CNC-milled. This fabrication

technology also is introduced in this course. In other words, it is a good

opportunity to understand how a real fabrication work with the technologies

which we are learning at present.

The key

concept that I really want to make this fabrication is that this project is good

example for the whole structure based on digital design. That is to say, the

whole structure of this project is assisted by computer program rather than

hand drawing. According to Jan-Peter Koppitz from Arup and Gregory Charles

Quinn from Swinburn University Technology (2012), the major 3D model is made by

Rhino produced by Mayer H. Architects and then transfer to Arup for structure

sectors which could not miss the supports of Rhino. Therefore, the computer

program knowledges are essential for both design and fabrication.

Selected Design Element

This project

offers areas both inside and outside its structure, numerous spaces dedicated

to culture, trade and leisure. The Archaeological Museum, a farmer’s market and

farmers, an elevated plaza with seating for concerts or events, multiple bars

and restaurants and a panoramic terrace on the top of the parasols. The

Archaeological Museum is located in underground level, which is square shape.

The market is located on street level, which is combined with the plaza. This

offers a public open space for visitors with a free accessibility. An elevated

plaza is located in 5 meters above the market level. The parasols are the main

structure of this project, which offers the shadow for the city centre as

dominant element umbrellas with their fungal forms.

The selected

design element would be the parasols, which shows the main structure of the

project. Other elements are not going to consider for this fabrication. the

Parasol structure was designed as a square waffle-grid system of interlocking,

CNC-milled timber fastened with steel connectors and high-strength glue. In

this case, only square waffle-grid system of interlocking will be fabricated.

How is the Key Concept Reflected in the Design Studio?

I am doing a high-performance technology architecture at

present, so the fabrication always is a good knowledge to know. This stream is

about how the architectural elements (materials, layout and functions etc.)

highly performance with technology. In this case, generating the plywood

structure interlock system is a good way to know the property of this material

and to explore the possibility of this material to achieve the high

performance. Also, the free shape of this project is a challenge for digital

model, so this is a good chance for me to push my 3D-modelling techniques.

The physical model always is a good way to clearly present

the ideas and details of the project for the tutors or clients, a delicate physical

model may influence whether this project is successful or not. In design

studio, many times in the past, my ideas were limited by physical model and

then have to change the original idea to another. It is good opportunity to

know how the model making techniques work during this course. This will be a

huge help for freeing the mind when design in studio.

In this case,

it is also a good chance for the future working out of university. It is good

to know the Parasol structures were made of the

timber which is shaped by CNC-milled. This means that some technique for the

physical model also has the possibility for the real projects. Therefore,

mastering these techniques also benefit for the future career.

Geometrical Description of the Shape

Most visible is the huge timber structure resembling six

merging mushrooms of up to 28 m in height and 150 m in total length. Some of

the mushrooms seem to have angels with vertical. By measuring, there is 15

degree differing with vertical direction.

The geometry for the structure is based on a free-form,

outlining the tree-shaped

shading structures. The individual laminated wood plates

(LVL) are generated by cutting vertically in an orthogonal 1.5x1.5 meters

pattern through the free form.

The free form

of this project will use Rhino and Fusion 360 to create the 3D model and slicer

for fusion 360 to create the patterns.

Proposed Scale, Material, Technique

Proposed Scale, Material, Technique

The dimension of this project is 150 meters long X 75 meters

wide X 28 meters high. 1 to 200 is considered to this project, so roughly 750mm

X 375mm X 140mm.

Proposed scale: 1:200

Material: 1mm

plywood

Technique: Laser cutter

Technique: Laser cutter

Time commitment and budget

Digital

model making: 1 week

Laser

cutting file prepare: 2 days

Laser

cutting process: 1 day

Assembly: 1

day

Budget: 200

$ roughly

2.

RGS centre

in University of Monterrey

Key Concept

The second architectural precedent I chose is Centro Roberto

Garza Sada also is known as Gate of Creation which is designed by Tadao Ando in Mexico. There are three reasons choosing this specific precedent for

fabrication. Firstly, this project is constructed by cast concrete, the

monolithic, minimalist form bridges over a massive triangular void at its

centre. Therefore, the exploration of the casting form will be reached

during this fabrication processes. Secondly, it is a prism of perfect concrete,

which forms a large arch to create a huge open gate void without any column. In

this case, I could also explore the forced structure for the casting shape. Finally, the concept of this project is

meaningful, which used the whole building as a gate of the university. This is

a good way to learn how the concept to guide the building shape.

The key

concept that I am willing to make this fabrication is that the architectures of

Ando are creative, and he always use the creative and critical way to solve

architectural problems. In this university project, he used the entire building

as the gate and place the entrance under the arch, which is quite meaningful

and beautiful. For the structure, he played the concrete to test the possible

shape, which inspires me a lot. I want to learn the concept of this building by

fabricating the shape of this building to feel the light and shadow of

Ando’s.

Selected Design Element

This project

obtains a lot of beautiful indoor and outdoor spaces which has 21 laboratories,

3 exhibition spaces, 2 amphitheatres and diverse multipurpose indoor and

outdoor spaces. Located in a site of 20,700 square meters, its' dimensions from

axis are 99meters by 27meters. It has 6 levels of 5.4meters height. The outside

space unit with the mountains surrounding.

The selected

design element would be the shape of this building, which is a huge concrete

arch. The gate and windows may also be considered for fabrication, which aims

to show how Ando deals with the unit of the architectural elements with this

specific project.

How is the Key Concept Reflected in the Design

Studio?

In this case, casting the plaster is similar with casting the

concrete, which help me to understand how the positive and negative space work.

In design studio, concrete is the material which is frequently used in

projects. To understand the possibility of shape made of concrete is important

to achieve the creative projects.

It is also a good chance for the future working. The concrete

is extremely popular in modern architecture, and both of cast and

prefabrication use the positive and negative space. This means the make of

mould and how the casting work is fairy important for working in architectural

industry.

Geometrical Description of the Shape

It is a prism of perfect concrete, which from its top is

twisted towards the bottom, crisscrossing its edges and forming a large arch.

Two ruled surfaces are alabandite with the staggering of the precise ribs of a

concrete. The longitudinal section defined by the open space that crosses the

entire building, reflects an ascending path over the warped geometry. Generous

spatial sequences and spherical forums, open laterally to a fragmented urban

landscape.

The challenge of this fabrication is that the mould is hard

to make due to the twisted form and the pattern of the surface. Therefore, the

digital model will be made in fusion 360 and the physical mould will be

CNC-milled.

Proposed Scale, Material, Technique

The dimension of this project is 99 meters long X 27 meters

wide X 32.4 meters high. The proposed scale would be 1 to 500.

Proposed scale: 1:500

Material: Model: plaster casting

Mould:

foam

Technique: CNC-milled

Casting

Time commitment and budget

Time commitment and budget

Digital

model making: 1 week

CNC-milled: 1

days

Casting: 1 week

Budget: 100

$ roughly

3.

CIRRATUS

VASE

Key Concept

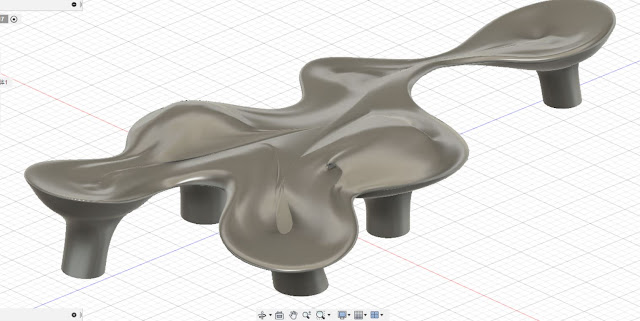

the third architectural precedent I chose is CIRRATUS VASE which

is designed by Zha Code (Zaha Hadid Computation and Design Group). There

are two reasons choosing this specific precedent for fabrication. Firstly, this

vase is based on a classic vase by architect Alvar Aalto and it is a way

to understand the form and space (2017). Secondly, this vase was made by

concrete 3D printer, the structure of the vase is layer-by-layer. Therefore,

the 3D potter would be used for this fabrication.

The key

concept that I am willing to make this fabrication is that the layer-by-layer

strategy could make beautiful and complex structure. Using 3D potter also is a

good chance to understand the different property of the clays.

Selected Design Element

The whole

vase is selected for this fabrication.

How is the Key Concept Reflected in the Design

Studio?

In this case, the technique of 3D potter is a good way to

make the physical model with the details of facade. It is a useful strategy to

present the details of model in high-performance technology studio.

Geometrical Description of the Shape

This vase is a bespoke algorithm produces

complex double-curvature geometry, and there are 220 concrete layers for this

vase.

Proposed Scale, Material, Technique

The dimension of this project is 400mm long X 400mm wide X

660mm high. The proposed scale would be 1 to 50.

Proposed scale: 1:50

Material: clay

Technique: 3d potter

Time commitment and budget

Digital

model making: 1 week

Layer test:

1 day

Process: 1

day

Dry: 1 day

Budget: 150

$ roughly

References:

John Wiley & Sons, (2017), 3D-Printed

Body Architecture, p112.

Christoph Gengnagel, A. Kilian,

Norbert Palz, Fabian Scheurer, (2011), Computational Design Modeling, chapter: matropol

parasol – digital timber design

Comments

Post a Comment