A3 - Documentation

Model 01 - Metropol Parasol - 1: 200

Size: 750mm length X 375mm width X 140mm height

Material: Basswood 1.5mm Thick

Technique: Laser Cutter

Pieces: 158

Step 01 : Digital Model Making

Step 03: File for Laser Cutter

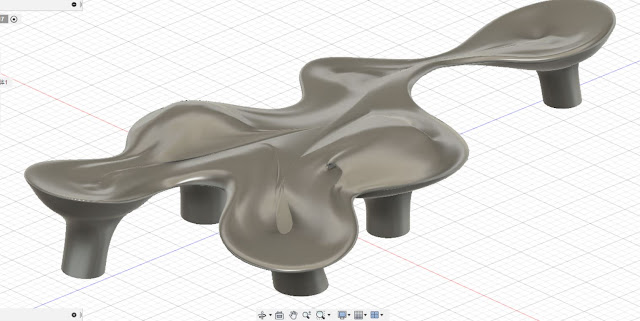

Model 02 - RGS centre in University of Monterrey - 1:500

Size: 198mm length X 54mm width X 64.8mm height

Material & Techniques:

Mould: CNC - Multicam Router - Blue Foam

Model: Casting - Plaster

Step 01: Digital Mould Making

Step 02: Physical Mould Making

Step 03: Preparing Plaster

Step 04: Casting

Fill the plaster and put overnight, the time depends on the properties of the plaster, if too wet, the plaster need more time to be dry.

Step 05: Take Out the Model

Model 03 - CIRRATUS VASE - 1:2

Size: 200mm length X 200mm width X 300mm height

Material: Stoneware Clay

Technique: 3D Pottery (Ceramic Printers)

Technique: 3D Pottery (Ceramic Printers)

Layers: 150

Step 01: Digital Model Making

|

The digital model was made by Rhino with the reference drawings, the reason used Rhino is because the oganic shape is easy to control in Rhino by using Loft tool.

|

Step 02: Try and Adjust the Digital Model

|

The first try is fail because

1. bottom is too small, and the top is big.

2. The transition in the middle too big to the clay collapsed.

|

|

The second try, I adjust the digital model to satisfy the clay properties and printed up side down to let the big part on the base, then the whole project was successfully processed.

|

Step 03: Wait and Complete

Waiting for the clay be dry and hard, then revise the project up side down, and add a base.

Comments

Post a Comment